Custom Lithium ion Cylindrical Battery Packs

Reliable and Customizable 18650 Battery Packs,High-Performance, Long-Lasting Power Solutions Sourced and Manufactured to Your Exact Specifications.

Our Cylindrical lithium Ion Battery Packs

Voltge Range: 3.7V,7.4V,11.1V,14.8V,18.5V,22.2V,32.4V...

Single Cell Capacity range:2000mAh~6000mAh

Lithium ion Cylindrical Battery

- 10.8V,3500mAh

- 3cell in seriese, 3S1P

- Max charging Voltage:8.5V

- Max discharging voltage:7.65V

- Standard charging current:700mA

- Max charging current: 3.5A

- Standard discharging current: 700mA

- Max continuouse discharging current:3.5A

- Peak discharging current for seconds: 10A

- Application: power tools

Lithium ion Cylindrical Battery

- 18.5V,2200mAh

- 5cell in seriese, 5S1P

- Max charging Voltage:21.25V

- Max discharging voltage:14V

- Standard charging current:440mA

- Max charging current: 2.2A

- Standard discharging current: 440mA

- Max continuouse discharging current:2.2A

- Peak discharging current for seconds: 22A

- Application: power tools, auto-mower etc

Lithium ion Cylindrical Battery

- 18.5V,2600mAh

- 5cell in seriese, 5S1P

- Max charging Voltage:21.25V

- Max discharging voltage:14V

- Standard charging current:520mA

- Max charging current: 2.6A

- Standard discharging current: 520mA

- Max continuouse discharging current:2.6A

- Peak discharging current for seconds: 8A

- Application: auto-mower etc

Lithium ion Cylindrical Battery

- 7.4V,2600mAh

- 2cell in seriese, 2S1P

- Standard charging current:520mA

- Max charging Voltage:8.6V

- Max discharging voltage:5.6V

- Max charging current: 2.6A

- Standard discharging current: 520mA

- Max continuouse discharging current:2.6A

- Peak discharging current for seconds: 5.2A

- Water Proof: IP6

- Application: Flash lights/Hand torch

Lithium ion Cylindrical Battery

- 7.4V,5200mAh

- 2cell in seriese 2 cells in parallel, 2S2P

- Standard charging current:1040mA

- Max charging Voltage:8.6V

- Max discharging voltage:5.6V

- Max charging current: 5.2A

- Standard discharging current: 1040mA

- Max continuouse discharging current:5.2A

- Peak discharging current for seconds: 10.4A

- Water Proof: IP6

- Application: Flash lights/Hand torch

Lithium ion Cylindrical Battery

- 14.8V,5200mAh

- 4cell in seriese 2 cells in parallel, 4S2P

- Max charging Voltage:17.2V

- Max discharging voltage:11.2V

- Standard charging current:1040mA

- Max charging current: 5.2A

- Standard discharging current: 1040mA

- Max continuouse discharging current:5.2A

- Peak discharging current for seconds: 10.4A

- Water Proof: IP6

- Application: Flash lights/Hand torch

Lithium ion Cylindrical Battery

- 18.5V,2600mAh

- 5cell in seriese, 5S1P

- Max charging Voltage:21.25V

- Max discharging voltage:14V

- Standard charging current:520mA

- Max charging current: 2.6A

- Standard discharging current: 520mA

- Max continuouse discharging current:2.6A

- Peak discharging current for seconds: 8A

- Application: auto-mower etc

Lithium ion Cylindrical Battery

- 32.4V,2500mAh

- 9cell in seriese, 9S1P

- Max charging Voltage:38.25V

- Max discharging voltage:25.2V

- Standard charging current:1250mA

- Max charging current: 2.5A

- Standard discharging current: 1250mA

- Max continuouse discharging current:7.5A

- Peak discharging current for seconds: 10A

- Application: automower etc

Lithium ion Cylindrical Battery

- 18.5V,2500mAh

- 5cell in seriese, 5S1P

- Max charging Voltage:21.25V

- Max discharging voltage:14V

- Standard charging current:1250mA

- Max charging current: 2.5A

- Standard discharging current: 1250mA

- Max continuouse discharging current:20A

- Peak discharging current for seconds: 30A

- Application: auto-mower etc

What can we custom Lithium ion battery packs?

How can we help you build the custom Lithium ion battery packs?

#1 Providng 3D drawing for battery outer case

Involves considering dimensions, material, mounting features, and safety. Below is a step-by-step guide:

A. Inner Dimensions

- Add 0.2–0.5mm clearance for easy insertion.

B. Material Selection

- Plastic (ABS, PETG, Nylon): Lightweight, non-conductive.

- Metal (Aluminum): Better heat dissipation (for high-power cells).

C. Mounting & Contacts

- Spring contacts or pogo pins for terminals.

- Snap-fit or screw mounts for secure placement.

- Vent holes (safety in case of gas buildup).

D. Thermal Management

- Heat sinks (for high-current applications).

- Airflow channels if enclosed.

Multi-Cell Battery Pack (2S-4P)

- Spacing: 1–2mm between cells (prevents overheating).

- Bus bars: Model conductive paths (copper/brass inserts).

- BMS slot: Reserve space for a PCB.

#2 Choosing the right Cylindrical Lithium ion Cells for your projects

1. Understand Common Cylindrical Li-ion Cell Types

The most widely used cylindrical Li-ion cells follow standardized sizes (e.g., 18650, 21700, 26650, 32650). Key differences include:

18650 (18mm × 65mm):3.6-3.7V, 2000-3500mah Common in laptops, flashlights, and small power banks.

21700 (21mm × 70mm): 3.6-3.7V, 4500-5000mah Higher capacity/power (used in EVs, power tools).

26650 (26mm × 65mm): 3.2V, 4000-4500mah Higher capacity, used in solar storage and high-drain devices.

32650 (32mm × 65mm): 3.2V, High capacity 6000mah, used in industrial applications.

Others: 18500(1800mah), 14500(800mah),16500(1000mah),18350(900mah)

2. Key Parameters to Consider:

A. Capacity (mAh or Ah)

B. Cell Voltage (Nominal & Max)

Nominal voltage: 3.2V, 3.6V,3.7V (Li-ion).

Max voltage: 4.2V (fully charged).

C. Discharge Rate (Continuous & Peak)

Standard cells: 1C–3C (e.g., 2A max for a 2000mAh cell).

High-drain cells: 10C–30C (e.g., power tools, drones).

Check continuous & pulse discharge ratings.

D. Chemistry & Performance

NMC (LiNiMnCoO₂): Balanced energy/power (EVs, power tools).

LFP (LiFePO₄): Safer, longer lifespan, but lower energy density.

LCO (LiCoO₂): High energy density (consumer electronics).

E. Cycle Life (Durability)

Standard cells: 300–500 cycles (to 80% capacity).

High-quality/LFP cells: 2000+ cycles.

F. Temperature Range

Charge: 0°C–45°C (some support low-temp charging).

Discharge: -20°C–60°C (performance drops in extreme temps).

3. Top Brands & Reliability

Panasonic/Sanyo (NCR18650B, high capacity).

Samsung (30Q, 25R for high drain).

LG Chem (HG2, MJ1 for energy/power balance).

Sony/Murata (VTC6 for high power).

EVE, Lishen (budget-friendly alternatives) and others

4. Application-Specific Recommendations:

Small DIY Electronics: 18650 (Panasonic NCR18650B, 3400mAh) High capacity, reliable.

High-Power (Drones, RC) :21700 (Samsung 40T, 4000mAh, 35A) High discharge, energy density.

Solar Storage :26650 (EVE 26650, 5000mAh, LFP) Long lifespan, stable.

Budget Projects :18650 (Samsung 25R, 2500mAh, 20A or others) Affordable, good power output.

#3 Designing the right PCB or BMS

A Battery Management System (BMS) is an electronic circuit that monitors, controls, and protects a battery pack. Its key functions include:

- Overcharge Protection: Prevents damage from excessive voltage.

- Over-Discharge Protection: Prevents damage from excessive discharge.

- Over-Current Protection: Protects against excessive current draw.

- Short-Circuit Protection: Prevents damage from short circuits.

- Cell Balancing: Ensures all cells in a series string have the same voltage.

- Temperature Monitoring: Prevents operation outside safe temperature ranges.

- State of Charge (SoC) Estimation: Provides an estimate of the remaining battery capacity.

- Communication: (Optional) Provides data to a host device (e.g., a microcontroller).

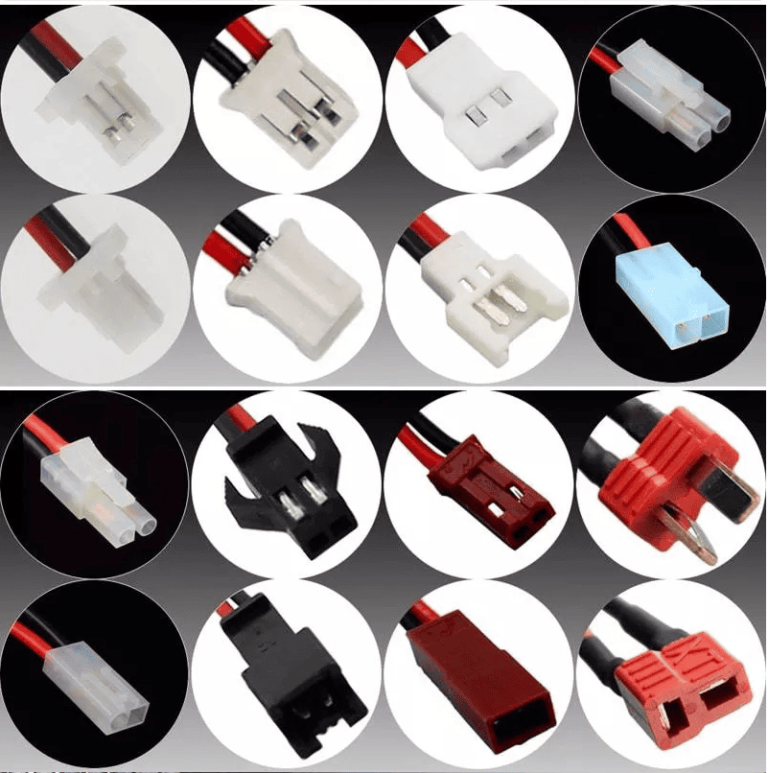

#4 Choosing the right connector, terminals or contacts

1. Key Factors to Consider

| Factor | Why It Matters |

|---|---|

| Current Rating | Must handle max discharge current (e.g., 10A vs. 30A). |

| Voltage Rating | Should exceed battery voltage (e.g., 12V, 24V, 48V). |

| Connection Type | Soldered, spring-loaded, screw terminals, etc. |

| Durability | Cycles (how many insertions before wear). |

| Safety | Spark-proof, reverse-polarity protection. |

| Size & Space | Fits within enclosure. |

2. Common Connector Types for Li-ion Batteries

A. Low-Current (≤5A) – Small Electronics

-

JST-PH / JST-XH, Molex (1.0mm–2.54mm pitch)

- Used in: small battery packs.

- Pros: Cheap, lightweight.

- Cons: Not for high current.

B. Medium-Current (5A–20A) – Power Tools, E-Bikes

-

XT30 / XT60 / XT90 (Amass Connectors)

- Used in: Drones, RC models, e-bikes.

- Pros: High current, secure locking.

- Cons: Bulky for small projects.

-

Anderson PowerPole (15A–45A)

- Used in: Ham radio, solar power.

- Pros: Modular, handles high current.

C. High-Current (20A–100A+) – EVs, Solar Storage

-

Bullet Connectors (4mm–8mm)

- Used in: Custom battery packs, EV conversions.

- Pros: High current, easy to solder.

- Cons: No locking mechanism.

-

Molex / TE Automotive Connectors

- Used in: Electric vehicles, industrial.

- Pros: Waterproof, vibration-resistant.

-

Lugs & Ring Terminals

- Used in: Stationary battery banks.

- Pros: Best for screw terminals

Applications for Cylindrical lithium ion Battery Packs

Our Li-ion batteries store the excess solar energy generated during the day, allowing you to use it at night or during peak demand times. This significantly reduces your reliance on the grid, lowering your energy bills and increasing your energy independence,provide reliable backup power during grid outages, ensuring your essential appliances.Our Li-ion batteries utilize advanced cell technology and a sophisticated Battery Management System (BMS) that optimizes performance, protects against overcharging and over-discharging, and ensures a long lifespan.

Our Li-ion batteries store the excess solar energy generated during the day, allowing you to use it at night or during peak demand times. This significantly reduces your reliance on the grid, lowering your energy bills and increasing your energy independence,provide reliable backup power during grid outages, ensuring your essential appliances.Our Li-ion batteries utilize advanced cell technology and a sophisticated Battery Management System (BMS) that optimizes performance, protects against overcharging and over-discharging, and ensures a long lifespan.

Factory and Capability View

Focus on Lithium ion battery packs for 9+ years

The Battery Manufacturing Process

1. After the samples and battery specification are confirmed, we will start mass production soon after receiving the customer order and deposit.

2. Evaluate supplier, and test the quality of cell and PCM samples, till samples are approved.

3. Buy all the materials from the qualified supplier which are CE, ROHS,UKCA certified.

4. Spot-check cells capacity and fully check the voltage and internal resistance of cells before mass production.

5. Start mass production.

6. Fully check the battery quality during mass production, called IPQC.

7. After batteries are finished, fully check their performance, such as appearance, voltage, working current, over-working current, internal resistance etc. For the multiple battery pack, we add the life cycle testing before shipment.

8. Package and shipment.

Quality Inspection

Process during production

IQC

When we receive incoming materials from our suppliers, we conduct spot-checks on samples to assess their quality. If the samples pass the quality inspection and meet our standards, we proceed to transfer them to our incoming materials warehouse. From there, our production team will retrieve the approved materials for trial orders and, subsequently, for mass production based on the specified order quantity.

However, if the spot-check reveals that the samples do not meet our quality requirements and are not approved, we will arrange to return these materials to our supplier. This ensures that we maintain high standards and only use materials that meet our quality criteria in our production processes.

IPQC

Before proceeding with trial orders or mass production, we follow a thorough process to ensure the quality of the cells used in our products. This involves spot-checking the capacity of the cells and conducting a comprehensive assessment of their performance, including outward appearance, voltage, and internal resistance. Only cells that meet our quality standards are allowed to move forward to the production line.

Any cells that are found to be non-compliant during the spot-check are identified as “NG batteries” (No Good) and are immediately removed from the production process. These rejected batteries are then returned to the supplier for further analysis and resolution.

Once the approved cells have been soldered with PCM (Protection Circuit Module), we subject the batteries to a rigorous performance check. This assessment includes evaluating voltage, internal resistance, and overcurrent capabilities, among other factors. This meticulous testing ensures that the batteries used in our products meet our high-quality standards and guarantees the reliability and safety of the final goods.

OQC

When the batteries are depleted, we will conduct a thorough assessment of their performance based on the specifications or drawings confirmed by the customer. This assessment includes inspecting the outward appearance, battery label, printing, wires or wire connectors, voltage, internal resistance, and over current protection. If all these parameters meet the required standards, we will proceed with packing the batteries into cartons.

However, if any of these aspects do not meet the specifications, the batteries will be returned to the Quality Control (QC) team for further analysis and necessary adjustments.

In the case of multiple battery packs, such as two cells in parallel, five cells in series, or a 2P6S battery pack, we will subject them to life cycle testing before shipping.

This testing involves simulating real-world usage conditions to evaluate the battery pack’s performance and durability over an extended period. Only those battery packs that pass the life cycle testing will be considered suitable for shipment.

Our commitment to quality assurance ensures that only reliable and fully compliant batteries are delivered to our customers.

After-sales service

Batterea.com offers after-sales services that go far beyond regular batteries and custom-made batteries. They are a comprehensive, continued service package for customers and the core of our company philosophy. Our members of staff are available to you anytime for all possible questions regarding our range of services.

A high level of customer satisfaction is our basis for successful long-term partnerships.

When you receive our battery, if there are any problems, no matter what the problem is, we will face them and reply to you with our solution as soon as possible.

The Shipping Process

Step 1

Design,Manufacturing and book for shipment

We buy the materials to meet your order requests, then start the mass production under our quality control. In the meantime, we will send UN38.3 documents to the forwarder for booking cargo space to avoid any delay.

Step 2

Packing the Boxes for Delivery,stick UN3480 on the carton

After production, our team will pack your order into cartons, stick UN3480 label on the carton.

Step 3

Customs Clearance and Loading

Once your order is packed, we load them onto vans and wait for them to be cleared by Customs.

Step 4

International Delivery

Once cleared, your order will then be shipped to you through international waters. You’ll receive a bill of lading in your email once the cargo is on board and a bill of lading by telex released when your shipment arrives.

FAQ's

Frequently ask questions

Yes,18650 batteries are known for their ability to provide high discharge currents, making them suitable for applications with varying power demands.

Suggested Storage temperature:20℃ -30℃. Li-polymer batteries should be stored in a cool, dry place at a partial state of charge (around 40-60% SOC) to prevent degradation. Extreme temperatures should be avoided during storage.

The lifespan of Li-polymer batteries is influenced by factors like usage patterns and charging practices, but they generally have a lifespan of 300-500 charge cycles.

No, Li-polymer batteries are not susceptible to the memory effect, a phenomenon where batteries lose capacity if not fully discharged before recharging.

+

Glorious Years

+

Happy Customer

+

Battery models

%

Satisfactions

Request for a quote today

Send us a message if you have any questions or request a quote. Our experts will give you a reply within 24 hours and help you select the right valve you want.